Learn the Difference Between a Particle Counter and a Nephelometer, and Why Monitoring Indoor Air Quality is Important

We can all recall our mothers telling us as children to go outside and get some fresh air. Who would have known just how important this statement was and is today? Unfortunately, air pollution affects the entire planet. You can't escape it, not even inside your home or at work. According to the United States Environmental Protection Agency (EPA), indoor air can be up to ten times more polluted than outside air.

With the attention COVID-19 has brought to public health, highlighting the urgent need for ventilation, there has been a heightened awareness of indoor air quality in office and residential environments. The market for particle counters to measure indoor air quality will continue to increase dramatically over the next several years. Aside from the pandemic, this forecast is attributable to the increased investments by pharmaceutical and biotechnology firms and the global adaptation of ISO standards. Additionally, there has been an increase in requirements for particulate-free air in many manufacturing applications.

Particle Counters 101

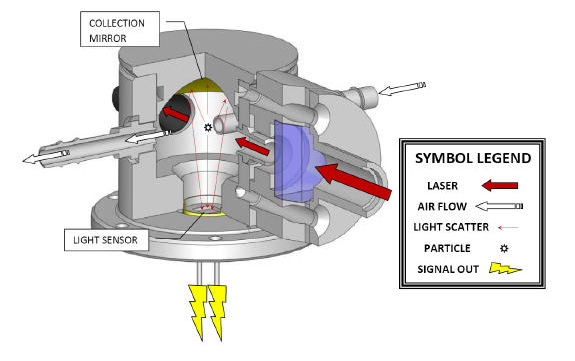

For practical applications, two kinds of particle monitoring instruments exist. The first instrument detects individual particles through light scattering technology and is known as an optical particle counter (OPC). The second instrument is called a nephelometer, which detects light scattering from an assembly of particles. This type of instrument may also go by the term photometer.

A few examples of particle counters Met One Instruments, Inc. manufactures include the ALL-NEW DR-528 eight-channel Particle Counter, the GT-324 four-channel Particle Counter, and the 804. Examples of nephelometers Met One manufactures include the E-Sampler Dual Ambient Monitor/Sampler, the ES-642 Remote Dust Monitor, and the BT-645 benchtop particle monitor.

A particle counter is a sophisticated monitoring instrument that measures the amount of particulate contamination in the air. Contaminants may be solid or liquid and biological or artificial in nature. A particle counter can be as simple as a handheld air-monitoring instrument or as advanced as a remote or multiplex manifold sequencing cleanroom system used for facility monitoring.

Nephelometers, also known as photometers, detect particles by measuring the total amount of light they scatter. The devices are useful as real-time dust monitors in:

- industrial hygiene applications,

- for concentration measurements of atmospheric aerosols, and

- in aerosol inhalation research.

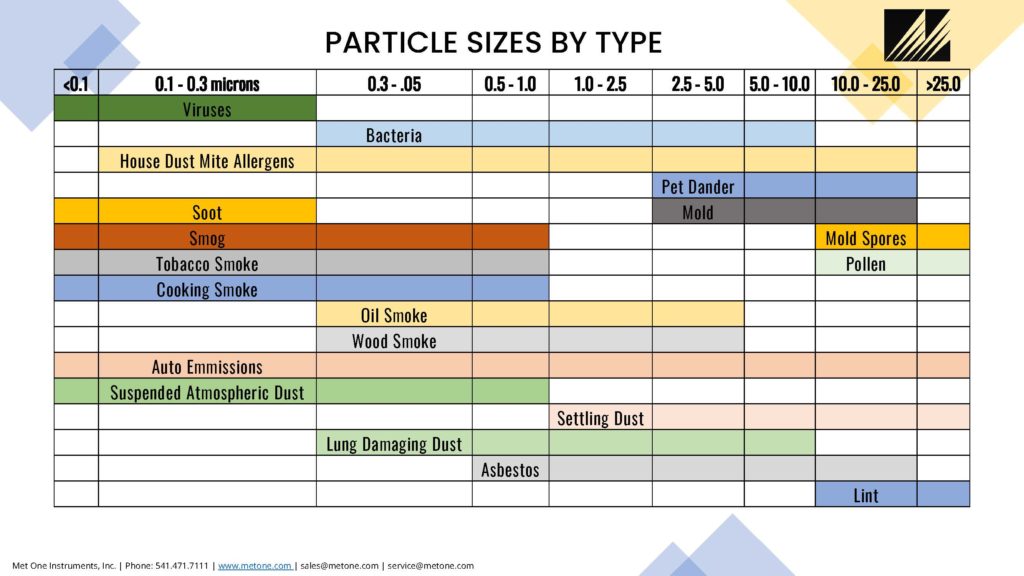

The intensity of light scattered by a particle is a function of the particle size, shape, and chemistry. The response is a function of particle size for unit mass concentration. Therefore, light-scattering instruments like aerosol nephelometers are usually limited to measuring particle sizes in the range of 0.1 to 10 microns. For reference, there are 25,400 microns in one inch.

Professionals use particle counters and nephelometers to determine how clean the air is for breathing, how pure the air is for packaging, and how safe food is for eating. They are also used in the manufacture of pharmaceuticals and microchips. Particle counters are commonly used to determine air quality by counting and sizing the number of particles in an air sample.

In addition to being either solid or liquid, airborne particulate contaminants may be biological or artificial in nature. Biological pollutants include mold, fungus, bacteria, viruses, animal dander, dust mites, pollen, human skin cells, or anything alive or living at one time. These are the biggest enemies of IAQ specialists because they are contaminants that cause health problems. Some examples of non-biological particulate contaminants include smog, tobacco smoke, soot, and cement dust.

Figure 1 shows the types and sizes of various particulate contaminants. This information helps one understand the character of particulate pollution inside a building or in ambient air. It is also helpful for understanding the cleanliness level in a controlled environment. Dust particles on furniture and those in a shaft of light are approximately 50 microns or larger. It may be possible to see particles as small as 10 microns; however, most harmful particles are not visible. Visible particles constitute only about 10 percent of indoor air particulate because these larger particles tend to settle quickly due to their weight. Smaller particles remain virtually suspended in the air until breathed in.

The Technology of Particle Counters

Like those manufactured by Met One Instruments Inc., particle counters use a light scattering method to count and size particles. Figure 2 shows the components of a typical light scatter-based optical particle counter. Ambient air is sampled by a tiny pump and then illuminated by a low-power laser diode. The laser illuminates particulate matter entrained in the sampled air, which is subsequently counted by a light-sensitive diode or similar device.

Optical Particle Counter vs. Nephelometer

An Optical Particle Counter is capable of counting and sizing individual particles. A Nephelometer provides an integrated output closely related to particle mass concentration. The application of an OPC or Nephelometer depends on the measured environment and any regulatory requirements. OPC's are required for measurements in cleanrooms or where the required measurements are in particles per liter. Nephelometers are required when the measurement needed is for mass concentration or micrograms per cubic meter.

Indoor Air Quality (IAQ) Concerns on the Rise

Aside from the pressing pandemic happening now, concerns about indoor air quality have increased partially due to energy conservation measures instituted in office buildings during the 1970s. These energy conservation measures resulted in the minimization of outside air infiltration and inadvertently contributed to the buildup of indoor air contaminants. This unforeseen consequence led to “Building-Related Illness,” in which buildings harbor polluted indoor air, leading to several health consequences for the occupants inside. “Sick Building Syndrome” is another IAQ-related problem that may be caused by inadequate ventilation, chemical contaminants from indoor or outdoor sources, or biological contaminants.

Complaints about IAQ related to Building-Related Illness or Sick Building Syndrome range from simple concerns, such as the air smelling odd, to the more complex, where air quality results in illness and lost work time. It may not be easy to identify a single reason for IAQ complaints because of the number and variety of possible sources, causes, and varying individual sensitivities.

Indoor air quality is regulated by the EPA and sometimes state or local agencies. These regulations follow recommendations by the American Society of Heating, Refrigerating, and Air Conditioning Engineers (ASHRAE). More recently, the Department of Homeland Security became interested in IAQ because of the potential of “poisoning” the air with airborne agents. An example of this includes anthrax and the threat of bioterrorism.

IAQ monitoring entails the measurement of three basic particle size categories (ASHRAE Standard 52.2 Minimum Efficiency Reporting Value (MERV)):

| Range 1 | 0.3 – 1.0 micron |

| Range 2 | 1.0 – 3.0 microns |

| Range 3 | 3.0 – 10.0 microns |

Why Use a Handheld Particle Counter?

A handheld OPC offers a portable solution for determining airborne particle concentrations. The primary use for handheld OPC's is to check contamination levels and locating sources of particle emissions. Their small size and weight offer a convenient and portable way to test indoor air quality, spot check or verify clean rooms, and test air filter efficiency.

These units are small enough to hold in one hand and are helpful for quickly collecting general information about the air in one location, then moving and checking another spot. Use of such equipment will provide an immediate response to occupant complaints or can be used as part of a comprehensive preventative maintenance program. Click here to learn more about how schools have incorporated daily testing with the Aerocet 831 into their preventative maintenance program.

Relevant Applications of Handheld Particle Counters

Medical Industry

Hospitals, clinics, and medical laboratories often monitor their air filtration systems for microorganisms such as bacteria or fungus particles. They also use OPC's in areas where patients with asthma or various other conditions are treated to verify optimal air quality.

Air Purifier / Filter Sales

Air purifiers and filters remove particles from the air stream. Testing these filters on a regularly scheduled basis is critical to their continued successful operation. Clogged or dirty filters are detrimental to circulated air quality throughout a building and often generate excessive airborne particulate matter.

Filter testing consists of visually inspecting the filter system and associated equipment for any apparent signs of damage. Airborne particulate sampling is recommended both upstream and immediately downstream of the filter. In most cases, a basic OPC is perfect for this application. Handheld particle counters offer an easy and convenient approach to test the effectiveness of air filters.

Cleanrooms & Controlled Environments

Cleanrooms and controlled environment areas, such as might be found in high-tech manufacturing, aerospace production, food processing, and beyond, are created to ensure that strict cleanliness, temperature, and moisture levels are maintained. Handheld particle counters are used in the certification of a cleanroom to verify that a specific particle threshold class is held.

HVAC Industry

Heating, air conditioning, and ventilation units and their ducts can be sources of mold, fungi, and other microbial pollutants, dust particles, secondary smoke, and organic material. Testing and cleaning HVAC systems and ductwork are achieved through various methods. Typically the “loosened” particulate matter is drawn throughout the HVAC systems, both before and after cleaning. Indoor air quality in an HVAC application can be quickly determined before and after the cleaning process with an OPC. A counter can also be used to verify equipment performance in building management and inspect equipment and ducting.

Selecting an Optical Particle Counter or Nephelometer

The growing interest in indoor air quality stimulates the development of instrumentation for IAQ research and building investigations. As one evaluates the available particle counters or monitors, it may be helpful to consider the following criteria:

1. Ease of use

iii. Ruggedness

iv. Time required for each measurement

2. Quality assurance

i. Maintenance and calibration requirements

ii. Availability of service and customer support

3. Output

i. Time-averaged vs. instantaneous readings

ii. Sensitivity

iii. Compatibility with computer or data logging accessories

4. Cost

i. Single-use only vs. reusable

ii. Purchase vs. rental

iii. Cost of ownership

In conclusion, OPC's and have been used in labs, cleanrooms, HVAC applications, and controlled environments, by IAQ specialists, air scrubber/ filter manufacturers, and environmental agencies worldwide.

As technology advances, there is growing concern about airborne contamination, both from a quality assurance perspective and in terms of the health and safety of individuals. In some cases, existing regulations must be met. Other times, guidelines prescribe the best practices. And in some situations, people have set their own standards for air quality and need to assess compliance with self-defined criteria. In all these scenarios, an accurate particle counter is a necessity.

Met One Instruments, Inc. provides proven air monitoring equipment to the US EPA (Environmental Protection Agency) used for air quality studies to measure the harmful effects of poor air quality on the human respiratory system. We are a frontrunner in the innovation and invention of new technologies to further explore and analyze our environment. We strive for excellence in the air quality industry.

The use of a Met One optical particle counter or nephelometer will dependably assist in analyzing the air you breathe. Count on Met One Instruments, Inc., one of the longest established instruments manufacturers in America, with a reputation for accuracy and precision, for your indoor air monitoring needs.

About the author

Marci Johnson leads the Handheld Particle Counter division at Met One Instruments, Inc.

Need More Information?

🔗 Read our Portable Particle Counters for Cleanroom Compliance guide.

🔗 Learn more about Public & Workplace Monitoring.

🔗 Read Industrial Hygiene 101 to better understand the importance of Environmental Health & Safety.

🔗 View the EPA’s “Evaluation of Emerging Air Sensor Performance” which spotlights two studies with the Aerocet 831 Particle Monitor.

Particle Counters Made by Met One Instruments, Inc.

🔗 ALL-NEW Aerocet 532 handheld dual Particle Mass Monitor & Counter

🔗 Aerocet 831 Aerosol Mass Monitor

🔗 ALL-NEW DR-528 Handheld Particle Counter

🔗 Model 804 Handheld Particle Counter

🔗 GT-324 Handheld Particle Counter

🔗 Learn about Met One’s standout cleanroom particle counter, the BT-620.

Nephelometers Made by Met One Instruments, Inc.

🔗 BT-645 Benchtop Particulate Monitor